Anypack Cost-Performance Box Making Machine

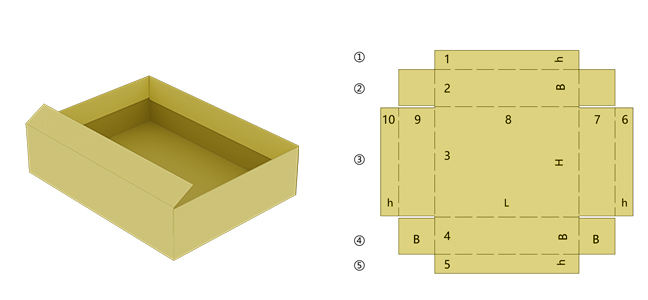

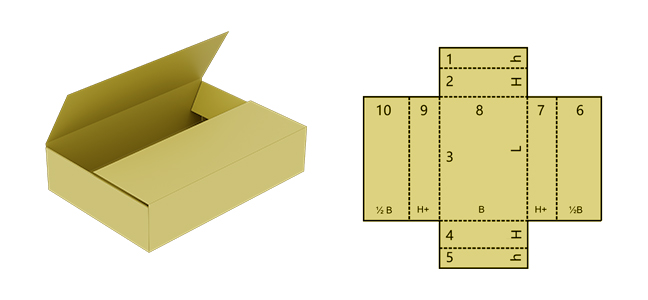

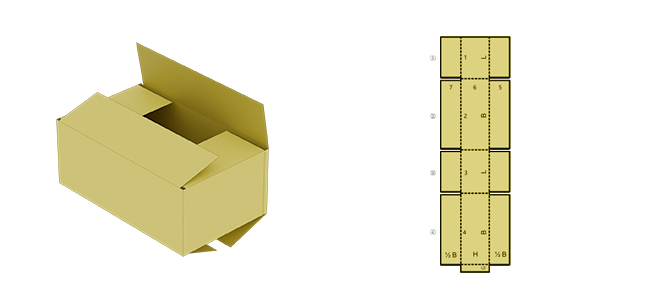

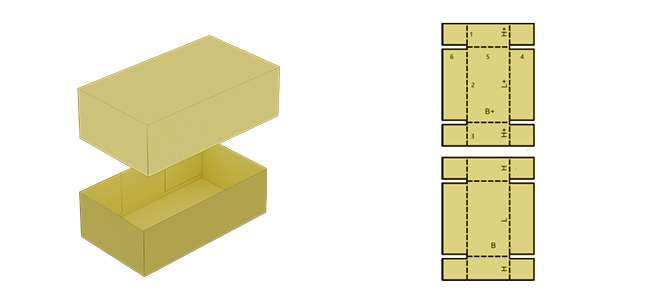

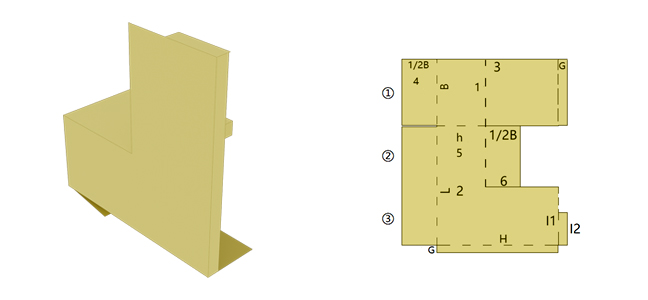

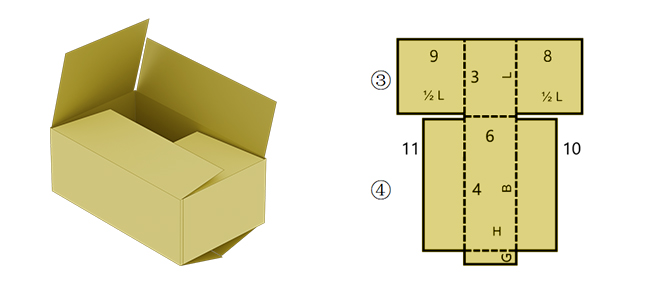

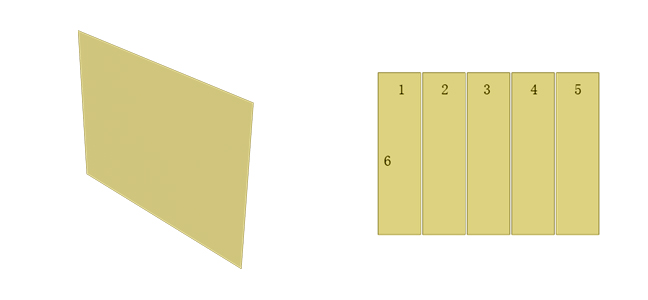

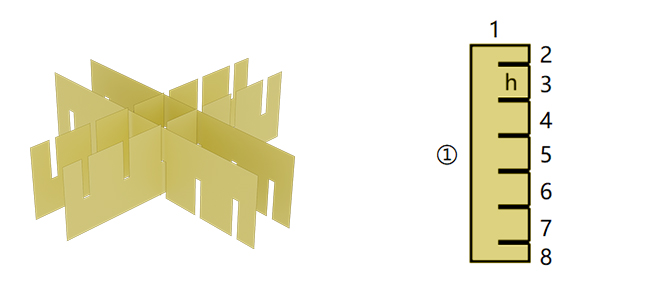

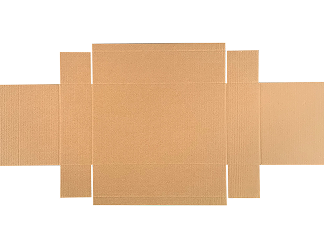

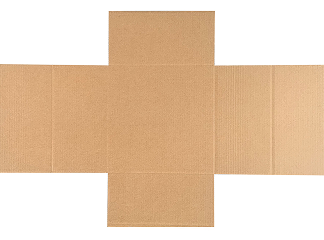

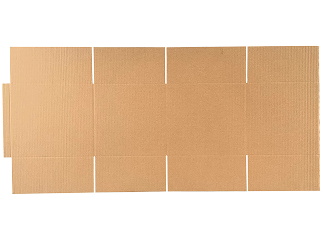

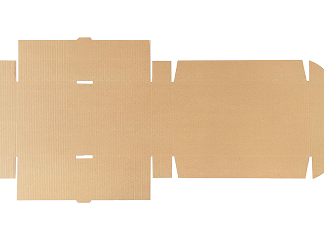

Offers over 150 corrugated box styles, plus full customization.

Slitting knives driven by independent power.

Switch between corrugated box styles in just 3 seconds.

Dual master creasing pattern.

Supports extra-large carton boxes up to 1700mm tall.

Operational Simplicity: Quick to install, easy to run

Redefining Short-Run Box Production

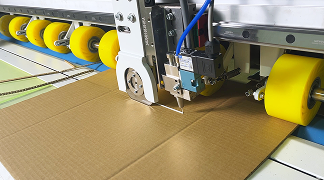

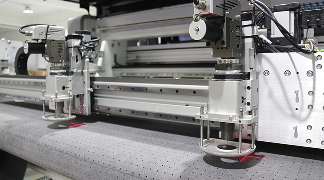

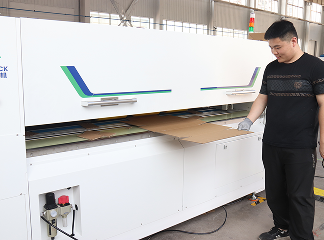

The AnyPack AB1800Pro, our advanced corrugated box making machine, is engineered to produce any size and style of box—from small batches to on-demand orders—with unmatched speed and precision. This fully automated, single-pass box making equipment integrates seamlessly into any production line.

Operating the AB1800Pro is remarkably simple: just load the corrugated board, choose your design on the intuitive touchscreen, and press start. The system then executes the entire process—from feeding and slotting to precise vibrating knife box cutting—in one compact, high-performance machine that makes boxes.

Your Custom Box. On Demand. It’s That Simple.

Standard Configuration

· 1 pcs paper feeding bracket

· 2 pcs 300mm slotting knives

· 1 pcs horizontal scoring beam

· 4 pcs vertical creasing wheels(driven by single servo)

· 4 pcs vertical slitting knives(driven by single servo)

· 1 pcs horizontal cutting knife

· 2 pcs 300mm slotting knives

· 1 pcs horizontal scoring beam

· 4 pcs vertical creasing wheels(driven by single servo)

· 4 pcs vertical slitting knives(driven by single servo)

· 1 pcs horizontal cutting knife

Major Functions Description of AB1800 Pro

Cardboard Feeding

Feed 10–50 sheets using vacuum technology for cardboard packaging boxes.

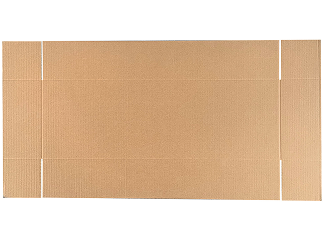

Horizontal Slotting & Scoring

This box making machine uses dual 300mm SKD11 slotting knives, performing slotting and scoring on the same beam.

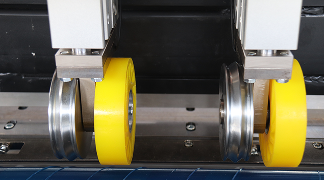

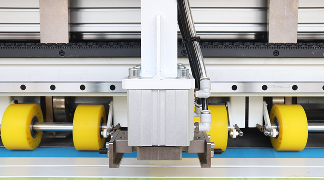

Vertical Creasing

4 creasing wheels driven by independent servo motor, misaligned

creasing and double-sided creasing can be achieved.

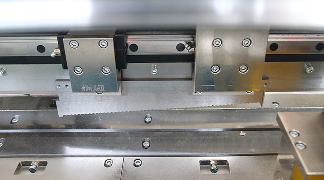

Vertical Slitting

4 slitting knives driven by independent power to rotate and cut,

making the carton box more beautiful and flat.

Horizontal Cutting

High speed makes the cardboard box edge free of burrs.

Gluing (Option)

Hot melt gluer or cold gluer, integrated in horizontal cutting knife,

high efficiency and versatility.

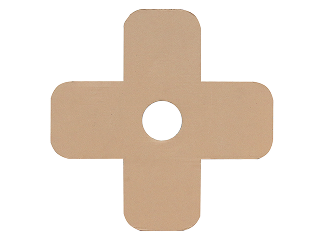

Punching (Option)

Handle, round, and custom holes for corrugated boxes – half or full punching available.

Vibrating Knife (Option)

Integrated in machine, accurate positioning, high efficiency, two

vibrating knives work at the same time and can move forward,

backward, left and right.

100+ customizable corrugated box options at your choice.

Carton

Factory

Corrugated Box Making Machine AB1800 Pro Specification

Model

1800 Pro

Equipment Size

2950*1600*1820

Power

380V,50-60HZ,10KW

Production Rate

500-600pcs/H

Cardboard Type

Sheet

Switchover time

About 3 seconds

Cardboard Thickness

1-12mm

Max Board Size

1800*Unlimited length

Min Board Size

150*150*1mm

Vertical Creasing

Quantity

4 wheels

Misaligned creasing

√

Min distance

20mm

Vertical slitting

Quantity

4 knives

Horizontal cutting

Quantity

1 knife

Max Box Height

1700mm(1800mm feeding board)

Feeding Mode

Automatic Feeding

Box types

More than 100

Weight

Appr 3200kg

Cardboard Box Making Machine Manufacturer FAQs

Are you a manufacturer of cardboard box making machine?

Yes, we are a direct manufacturer and exporter of box making machines located in Qingdao, China. With over 6 years of expertise in corrugated box manufacturing machine production, we have successfully partnered with numerous well-known brands and clients across the globe. Our facility maintains an annual production capacity exceeding 500 units of corrugated box making machines, carton box making machines, and related box making equipment. We warmly welcome you to visit our factory and see our manufacturing excellence firsthand.

What are the main differences between your machine and the

traditional box making machine?

① The ANYPACK system represents a technological leap in box making machines. As a fully integrated corrugated box maker machine, it performs slotting, scoring, cutting, and gluing in one continuous operation—replacing multiple standalone machines with a single, space-saving unit.

② Key advantages include: unlimited corrugated board length compatibility; 130+ pre-set box types with full customizability (no mold changes required); single-operator efficiency for reduced labor costs; and optimized performance for short-run orders. Together, these features deliver exceptional cost-effective value, making it the intelligent choice for modern packaging box making machine needs.

② Key advantages include: unlimited corrugated board length compatibility; 130+ pre-set box types with full customizability (no mold changes required); single-operator efficiency for reduced labor costs; and optimized performance for short-run orders. Together, these features deliver exceptional cost-effective value, making it the intelligent choice for modern packaging box making machine needs.

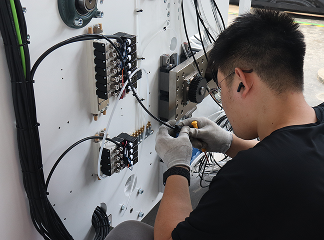

Could you please provide a brief overview of the structural design and key components of the ANYPACK AB1800 corrugated box making machine?

The ANYPACK AB1800 corrugated box making machine features a precision negative-pressure feeding system. This advanced method, unlike traditional machines, preserves corrugated board integrity. Its modular tooling includes servo-driven slotting knives, slitting knives, and creasing wheels on one plane, followed by a tail-cutting knife. A standard punching unit completes this all-in-one box making equipment, making it a highly efficient machine that makes boxes for short runs.

Could you share the warranty terms for the packaging box making machine?

Except for consumables, the warranty period of the ANYPACK

machine is one year.

What are the optional features of the ANYPACK box making machine?

Gluing(hot-melt glue, cold glue), printing machine (flexo

printing , digital printing machine), digital cutter (inside)

Is there any certification for Anypack corrugated box making machine?

We have the CE certification, and the third-party inspection

company SGS provides inspection services.

What is the lead time to dispatch of the box making machine?

The normal delivery time is 20 days from deposit, If it is the

peak sales season, it will be postponed accordingly.