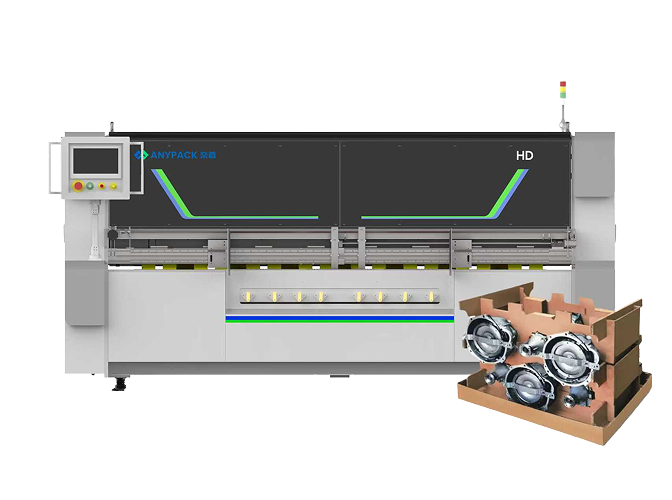

Heavy Duty Corrugated Boxes Making Machine AB2500HD

More than 100 pre-defined heavy duty box types

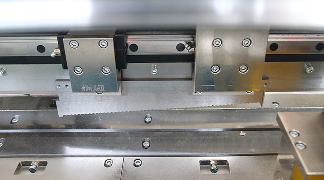

Slitting knives driven by independent power

Switchover time is about 3 seconds

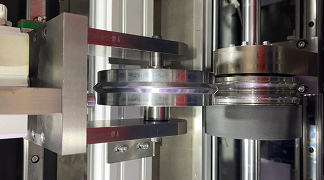

Dual master creasing pattern

2400mm extra large box height

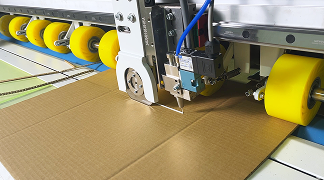

Single-Pass Vibrating Knife Cutting

Optional double-sided creasing design, achieving perfect folding

Heavy Duty Corrugated Boxes Making Machine AB3000HD

More than 100 pre-defined heavy duty box types

Slitting knives driven by independent power

Switchover time is about 3 seconds

Dual master creasing pattern

2900mm extra large box height

Single-Pass Vibrating Knife Cutting

Optional double-sided creasing design, achieving perfect folding

Redefining Heavy Duty Box Production.

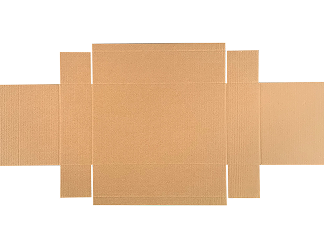

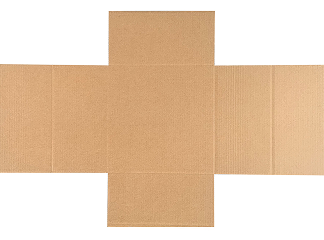

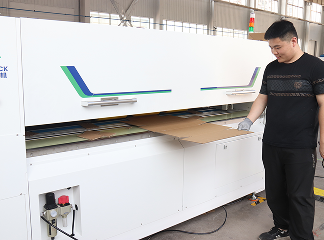

The Anypack heavy duty carton box making machine revolutionizes short-run production of heavy duty cardboard boxes. This fully automated corrugated box maker machine delivers any size or style—from sturdy shipping boxes to double wall boxes—in small batches with unmatched speed.

Simply load the heavy duty cardboard, select your design on the touchscreen, and press start. This compact corrugated carton box making machine seamlessly executes the entire process in a single pass: feeding, slotting, scoring, and precise vibrating knife cutting—all from one box making machine.

Your Custom Box. On Demand. It’s That Simple.

Standard Configuration

· 1 pcs paper feeding bracket

· 2 pcs 500mm slotting knives

· 1 pcs horizontal scoring beam

· 4pre-press wheels+4 pcs vertical creasing wheels(Creasing wheels switch between angular to concave and angular to flat be changed by touch panel.)

· 4 pcs vertical slitting knives(driven by single servo)

· 1 pcs horizontal cutting knife

· 2 pcs 500mm slotting knives

· 1 pcs horizontal scoring beam

· 4pre-press wheels+4 pcs vertical creasing wheels(Creasing wheels switch between angular to concave and angular to flat be changed by touch panel.)

· 4 pcs vertical slitting knives(driven by single servo)

· 1 pcs horizontal cutting knife

Major Functions Description of AB2500 HD

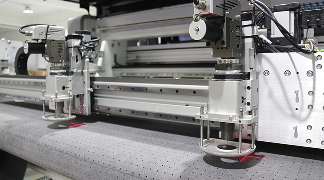

Cardboard Feeding

Simply load a stack of 10-50 sheets of heavy duty cardboard. The integrated vacuum suction system then grips and positions each sheet with precision, enabling accurate and reliable production of sturdy shipping boxes.

Horizontal Slotting & Scoring

Two 500mm slotting knives made of Japanese SKD11 steel ensure durable, high-precision slotting and scoring in one pass, ideal for producing heavy duty moving boxes and double wall boxes.

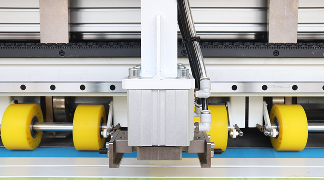

Vertical Creasing

Four servo-driven creasing wheels. Achieve misaligned or double-sided folds. Engineered for the precision demands of heavy duty shipping boxes production.

Vertical Slitting

4 pre-press wheels+4 creasing wheels driven by independent servo

motor, misaligned creasing and double-sided creasing can be

achieved.

Horizontal Cutting

High-speed cutting. Burr-free edges. Superior finish for heavy duty cardboard boxes.

Gluing (Option)

Hot melt gluer or cold gluer, integrated in horizontal cutting knife,

high efficiency and versatility.

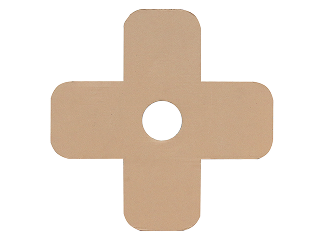

Punching (Option)

Handle hole, round hole, mold can be customized. Half punching and

full punching can be realized.

Vibrating Knife (Option)

Integrated in machine, accurate positioning, high efficiency, two

vibrating knives work at the same time and can move forward,

backward, left and right.

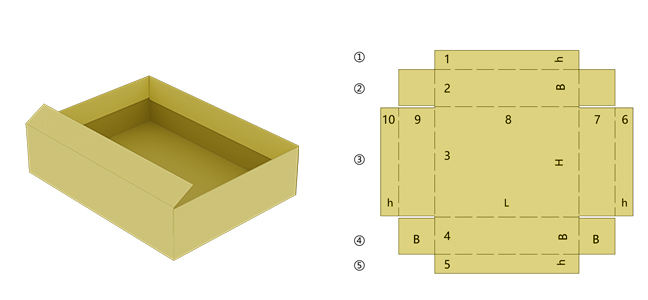

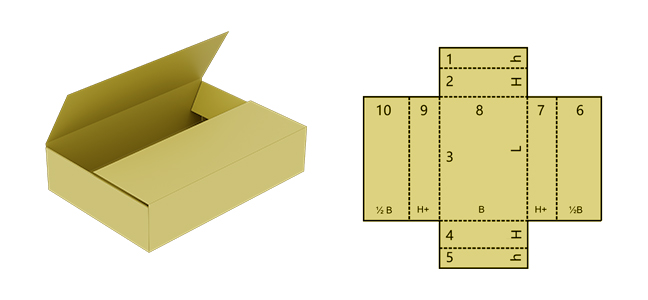

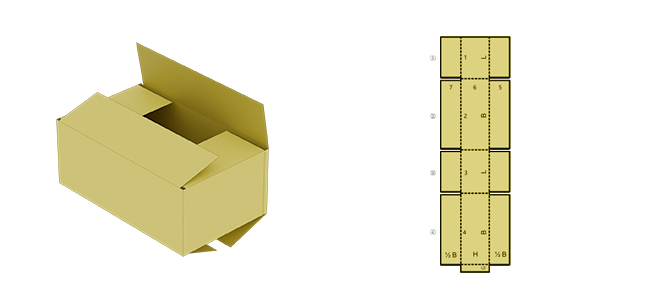

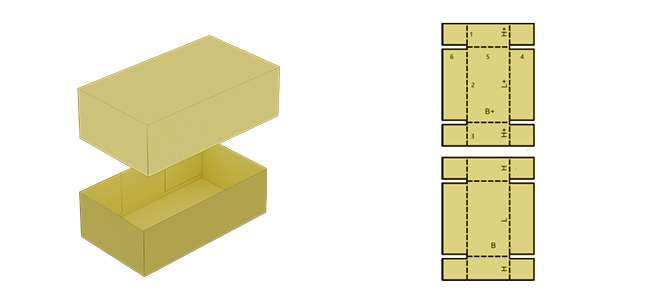

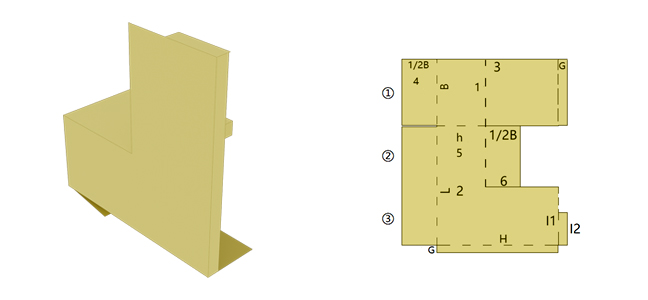

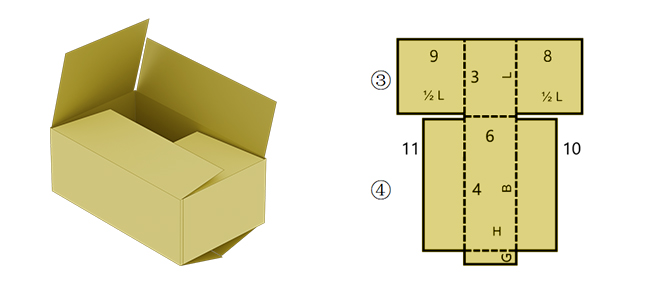

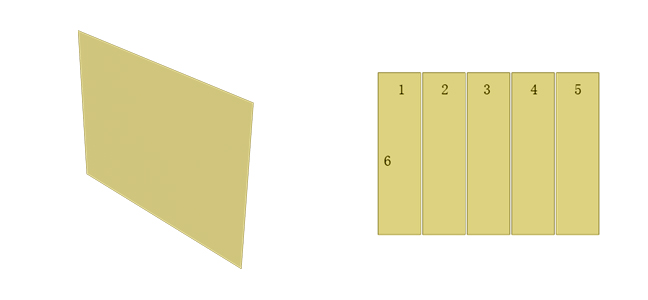

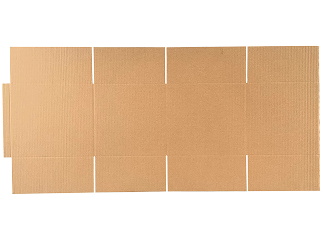

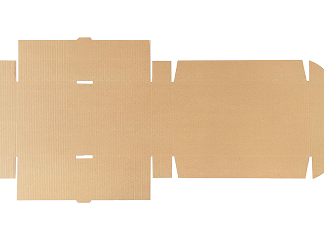

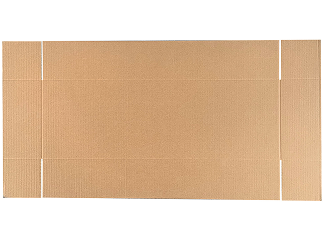

More than 100 box types for your choice

Carton

Factory

Corrugated Box Maker AB2500HD Specification

Model

2500HD

Equipment Size

3900*2100*2400

Power

380V,50-60HZ,20KW

Production Rate

500-600pcs/H

Cardboard Type

Sheet

Switchover time

About 3 seconds

Cardboard Thickness

3-22mm

Max Board Size

2500*Unlimited length

Min Board Size

710*430

Vertical Creasing

Quantity

4+4 wheels

Misaligned creasing

√

Min distance

20mm

Vertical slitting

Quantity

4 knives

Horizontal cutting

Quantity

1 knife

Max Box Height

2400mm(2500mm feeding board)

Feeding Mode

Automatic Feeding

Box types

More than 100

Weight

Appr 7000kg

Corrugated Box Machine Manufacturer FAQs

Are you a manufacturer of on-demand box making machine?

Yes, we are a direct sales manufacturer of box making machines

located in Qingdao, China, with more than 10 years of experience

in machinery manufacturing. We have cooperated with many

well-known brands and customers in many countries around the

world. The annual production capacity is as high as more than

500 units. Welcome to visit our factory.

What are the main differences between your machine and the

traditional box making machine?

① Slotting, scoring, creasing, slitting, cutting, punching,

gluing in one pass of our machine. Compared with traditional

machines that require the purchase of multiple parts, the

ANYPACK machine is more cost-effective and occupies a smaller

area.

② Traditional machines generally have restrictions on the length of corrugated cardboard, but the length of corrugated cardboard that can be used by the ANYPACK machine is unlimited.

③ The ANYPACK machine has 130+ pre-defined box types, which can be customized according to customer needs. It is convenient and fast, and there is no need to change the mold like traditional die-cutting machines.

④The ANYPACK machine only needs one person to operate, saving labor costs.

⑤More suitable for short-run orders.

⑥Highly cost-effective price.

② Traditional machines generally have restrictions on the length of corrugated cardboard, but the length of corrugated cardboard that can be used by the ANYPACK machine is unlimited.

③ The ANYPACK machine has 130+ pre-defined box types, which can be customized according to customer needs. It is convenient and fast, and there is no need to change the mold like traditional die-cutting machines.

④The ANYPACK machine only needs one person to operate, saving labor costs.

⑤More suitable for short-run orders.

⑥Highly cost-effective price.

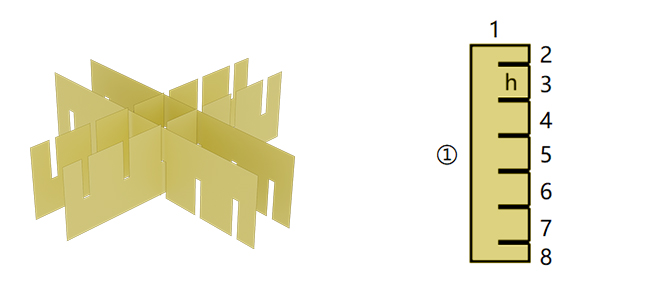

Could you please briefly introduce the structure of the

ANYPACK machine AB1800?

The ANYPACK AB2500HD uses negative pressure feeding by the

vacuum blower fan. Unlike traditional box making machine, this

feeding method protects the corrugated board flute type better.

There are 8 switches to adjust the fan adsorption area. Next are

two 500mm slotting knives, each equipped with an independent

servo motor. The slotting and the scoring contact are on the

same horizontal plane. Then we have four slitting knives and

eight creasing wheels(4pre-press+4 creasing wheels), all with

independent servo motors. Finally, there is a tail cutting knife

to cut off the excess cardboard on the rear side. Our machine is

also equipped with a punching as standard.

What is the warranty of the machine?

Except for consumables, the warranty period of the ANYPACK

machine is one year.

What are the optional features of the ANYPACK machine?

Gluing(hot-melt glue, cold glue), printing machine (flexo

printing , digital printing machine), digital cutter (inside)

Is there any certification for your equipment?

We have the CE certification, and the third-party inspection

company SGS provides inspection services.

What is the lead time to dispatch of the machine?

The normal delivery time is 20 days from deposit, If it is the

peak sales season, it will be postponed accordingly.